Kapsch Components provides Electronic Manufacturing Services such as assembling and testing of electronic products for the professional market ranging from small-batch to large scale production.

We also manage Logistic Services from inbound inspection, storage and warehousing, product packing and the shipment of finished goods to customers worldwide.

With our modern machinery park and decades of experience in a wide range of electronic manufacturing technologies, we offer high quality, flexibility as well as assistance in transforming prototypes into a serial production.

Core Technologies

Core Technologies

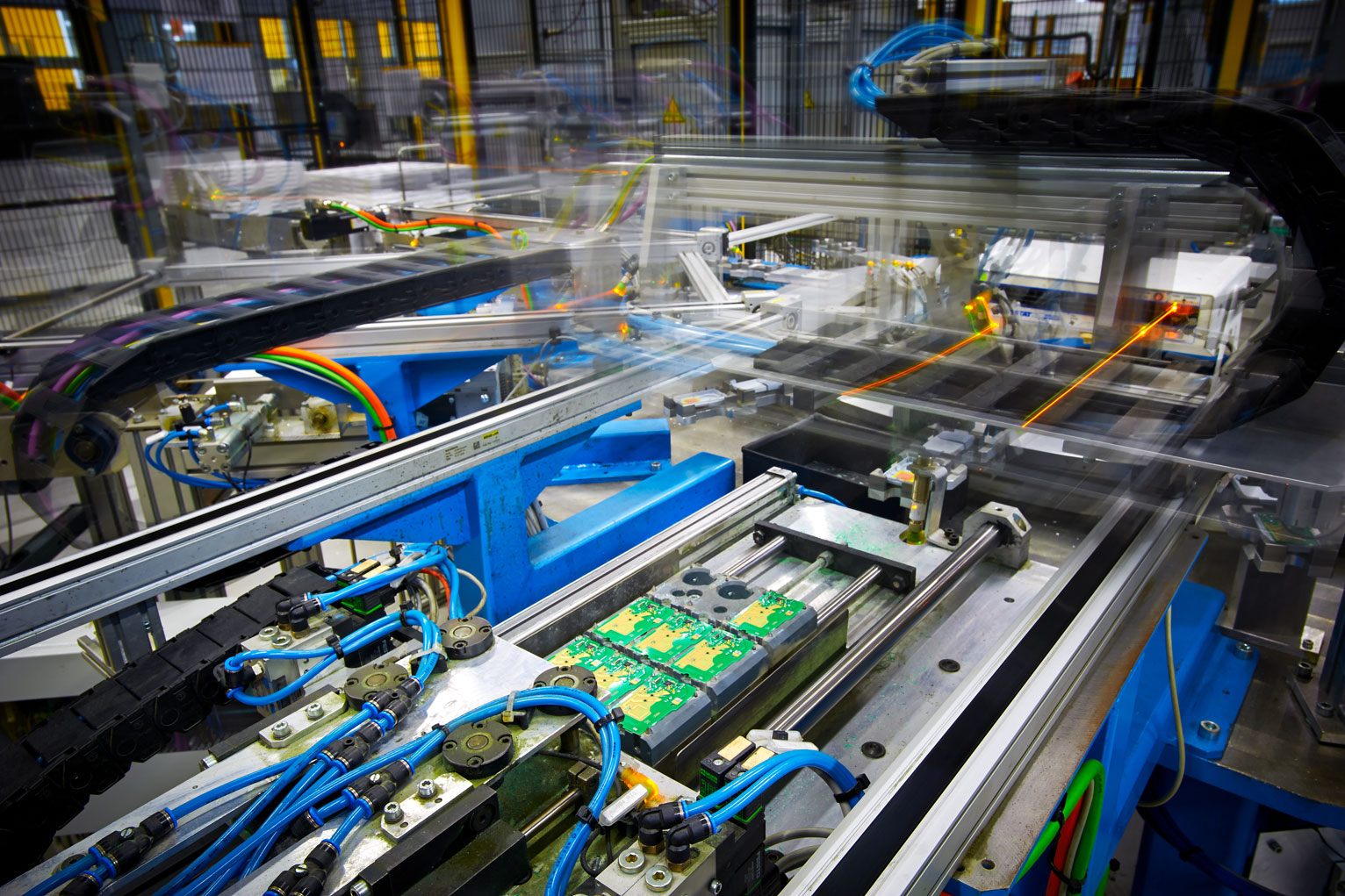

Surface-mount technologies (SMT); Through-hole Technology (THT) assembly; Automated Optical Inspection (AOI/AXI); wave, selective and laser soldering, Flying Probe Testing; Functional Testing; Burn-In, vibration and environmental testing; mechanical box-build and high-level complex automated assembly lines.

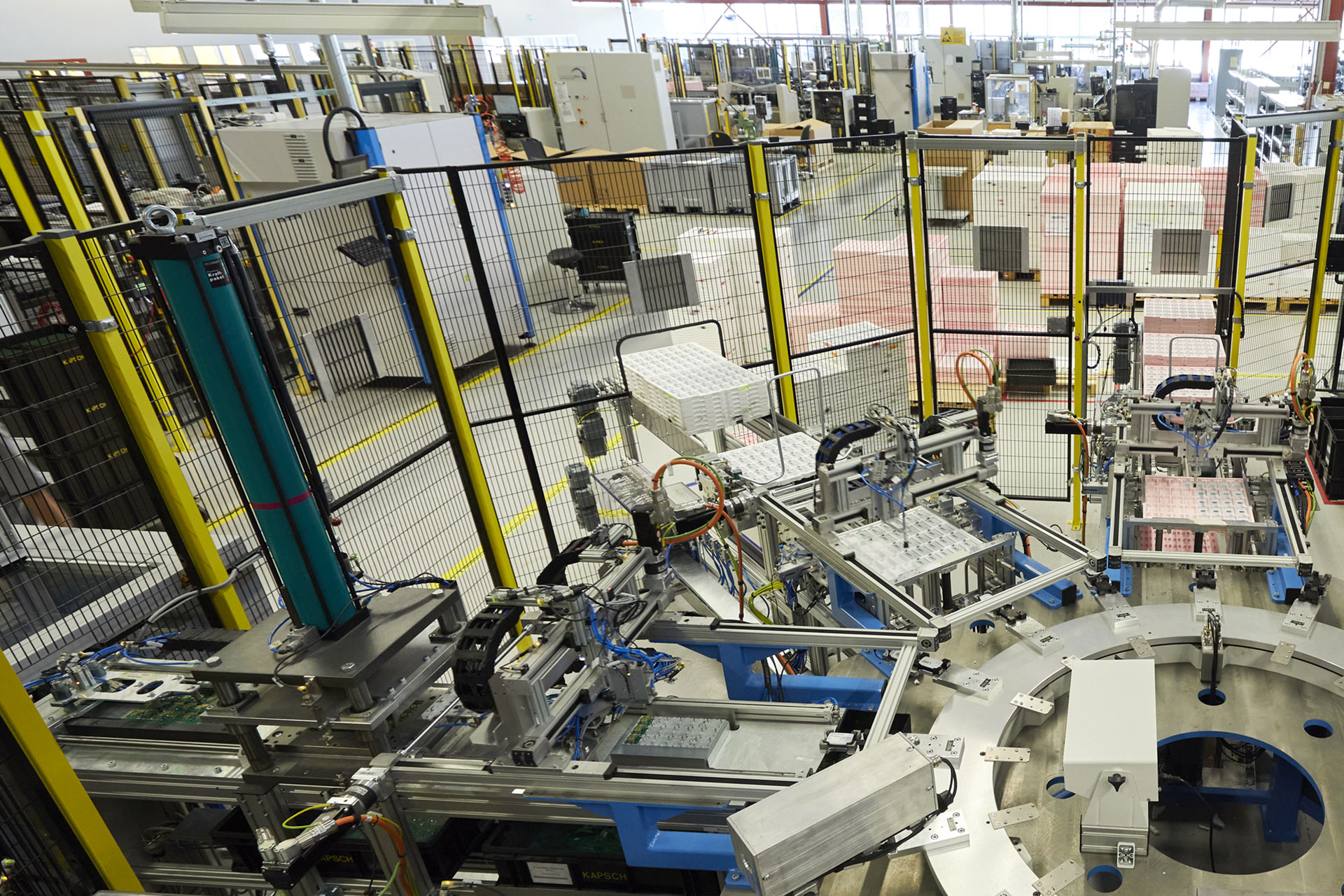

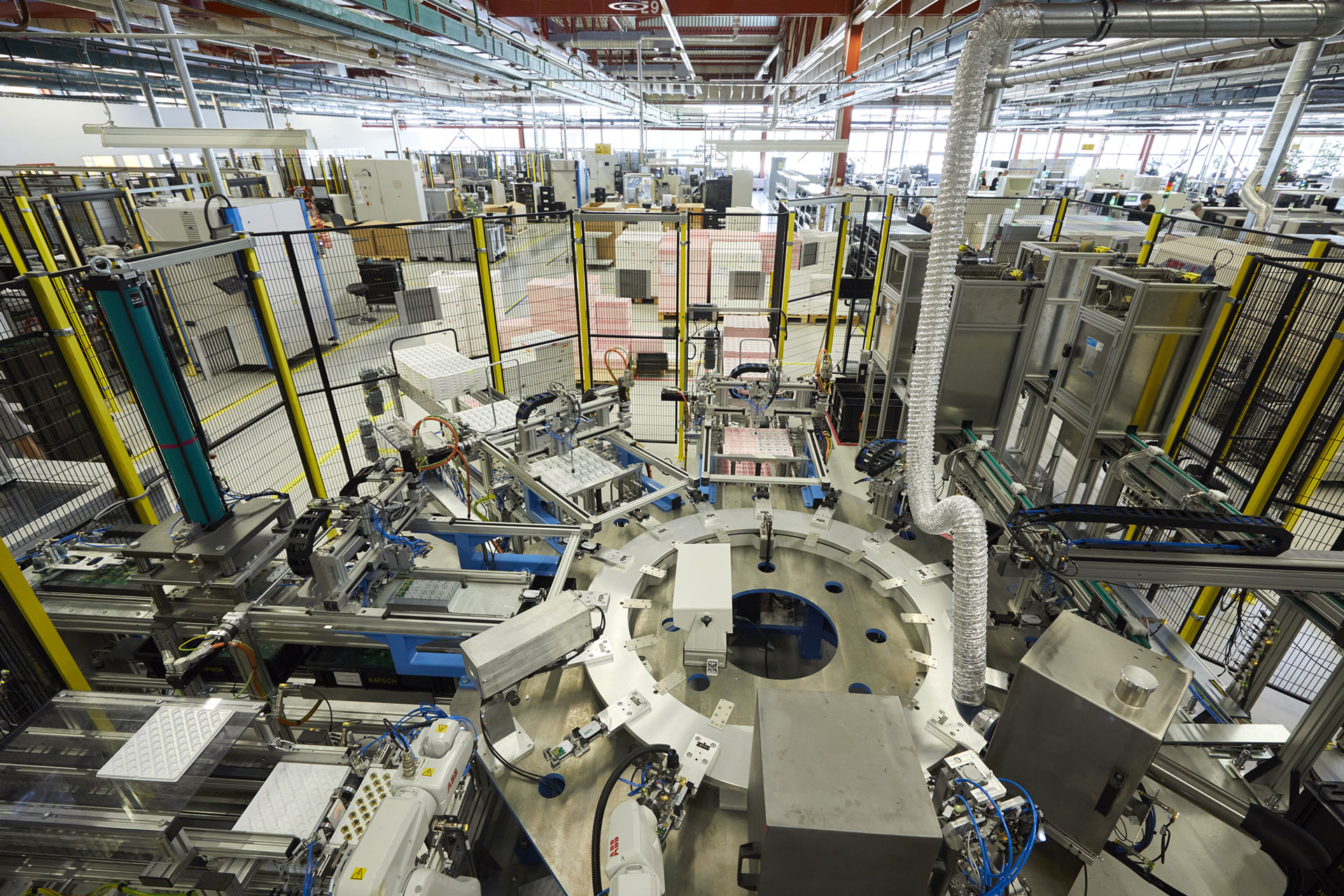

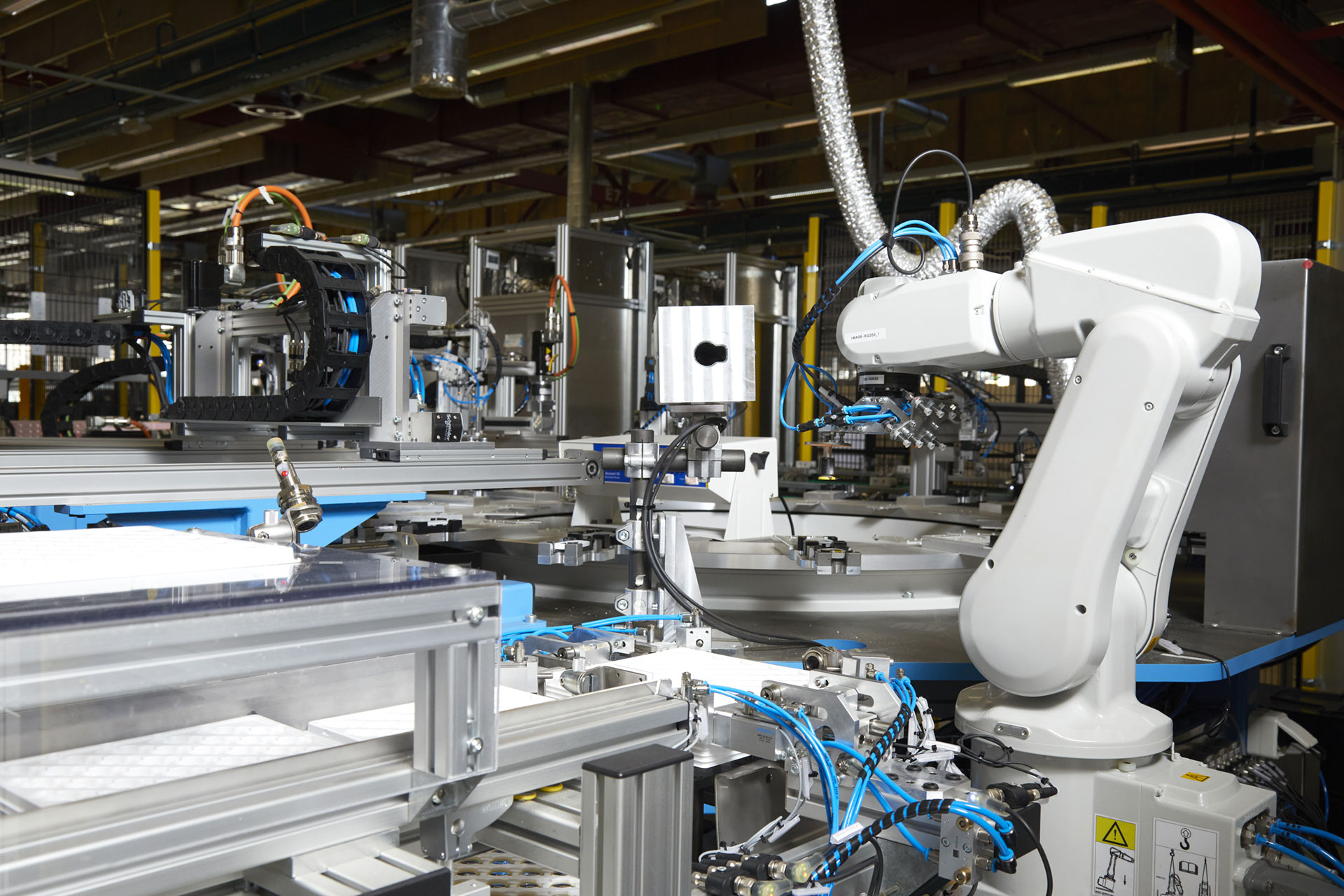

Automated Assembly

Automated Assembly

Complete automated assembly lines for PCBAs (Printed Circuit Board Assembly) and products, including various functional tests, product marking, traceability and packing of complete devices.

With our automation we offer high output, reliability, repeatability and foremost quality.

Improvement Methods

Improvement Methods

Kapsch Components works based on a LEAN production concept for continuous improvements:

5S, Value Stream Mapping, Poka Yoke, PFMEA, Kaizen and management boards, as well as Programs for Resource and Energy Efficiency.